Pay attention to the maintenance and maintenance of the electricity meter box mold this product, can prolong the service life of the product, and the service life of the product involves many aspects, and the production of raw materials has a great relationship with the product, the material characteristics of the electricity meter box mold:

I. Wear resistance

In the production of plastic parts, mold products bear greater pressure and friction, and the strength of raw materials for the production of electric meter box mold has certain requirements. In the manufacturing process of the product can withstand the force generated by the filling and flow of plastic, so manufacturers have great requirements on the hardness of the materials used in the manufacturing of the electric meter box mold, and the raw materials have excellent wear resistance to ensure the service life of the mold products and the reliability of the production of plastic parts.

2. Processability

Most of the electric meter box mold molding, also need to the mold part of a certain cutting and other special treatment, in order to improve the performance of the mold product level. Therefore, the hardness of the material must be moderate, with excellent machinability.

|

Part Name

|

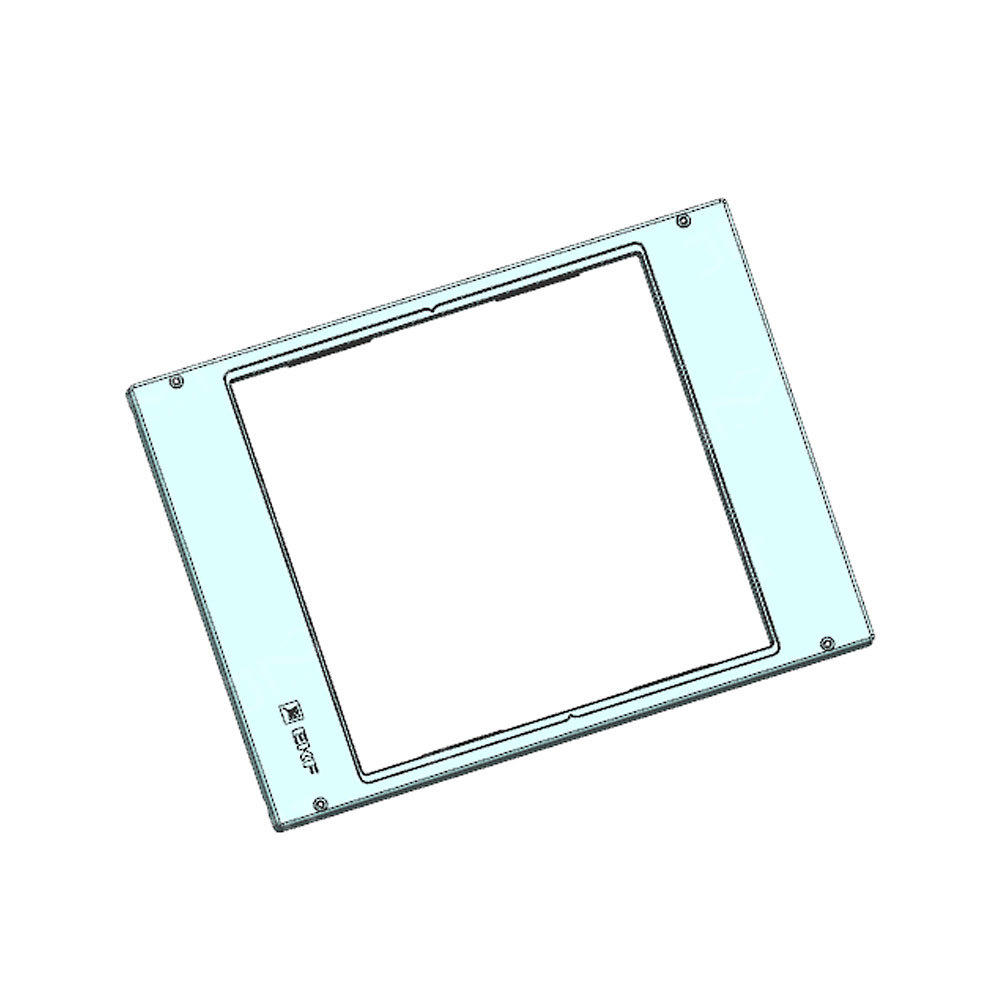

plastic electric meter box frame mould

|

|

Plastic resin

|

>PP<

|

|

Mould cavity steel

|

718

|

|

Mould Core steel

|

718

|

|

Gate system

|

Hot runner

|

|

Manufacture time (day)

|

60 DAYS

|

|

Mould life

|

1,000,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Tel: +86-18158622819

Tel: +86-18158622819  E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى