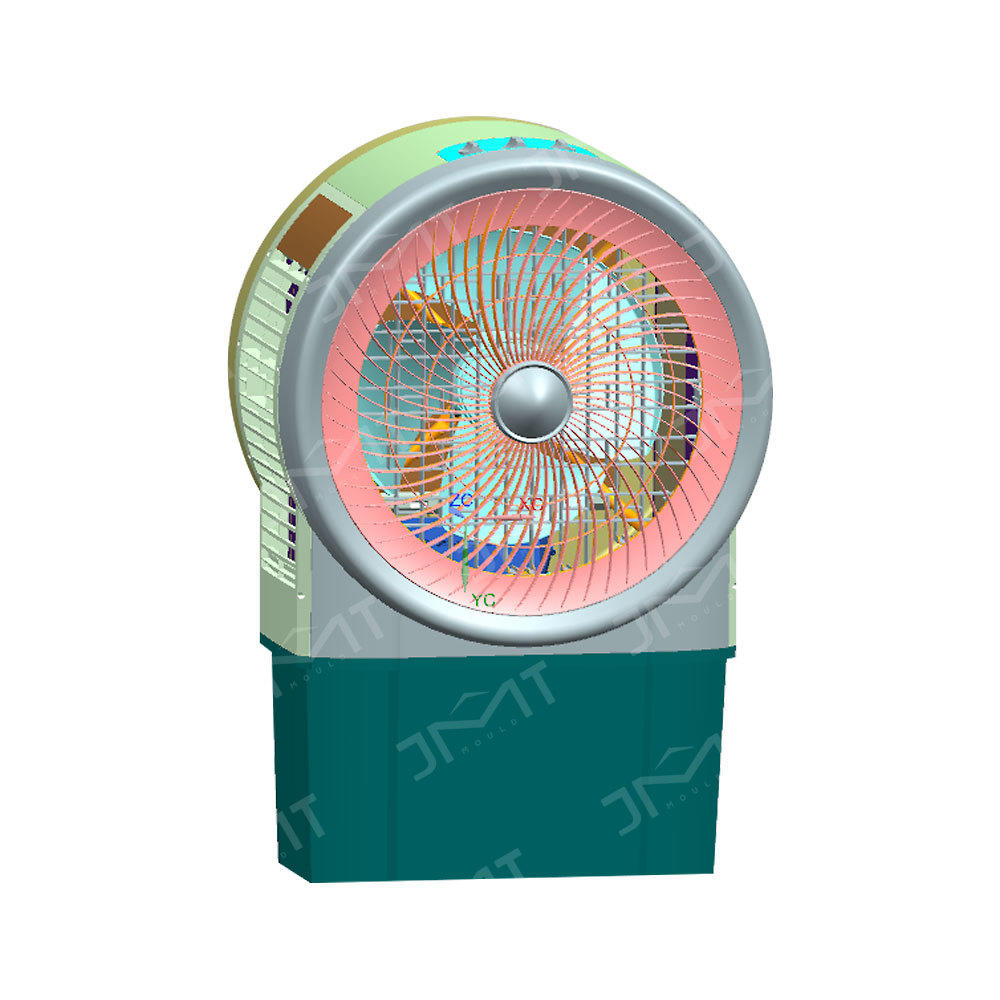

Advantages of our air cooler front cover mold:

1. High quality air cooler mold.

2. Creative plastic injection mold for home appliances, air cooler mold design

3. Punctual delivery time.

4. continuous service and support with english and other languages.

5. Coordinate customized r&d plan.

6. Experienced skilled workers.

7. Good post - sales service

During the processing of mold manufacturing:

1) The modification method should be considered when designing the mold, and there is enough space for modification.

2) The device of the mold should conform to the standard of anti-grating and long mold life.

3) Manufacturing technology and time are different from the hardness and tensile properties of materials.

4) Due to its precision, most of the work must be done by hand.

5) High quality molds should conform to good surface manufacturing and accuracy

|

Part Name

|

Plastic Air Cooler Front Cover mould

|

|

Plastic resin

|

>PP<

|

|

Mould cavity steel

|

1.2311H

|

|

Mould Core steel

|

1.2311H

|

|

Gate system

|

Hot runner

|

|

Manufacture time (day)

|

60 DAYS

|

|

Mould life

|

500,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Tel: +86-18158622819

Tel: +86-18158622819  E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى