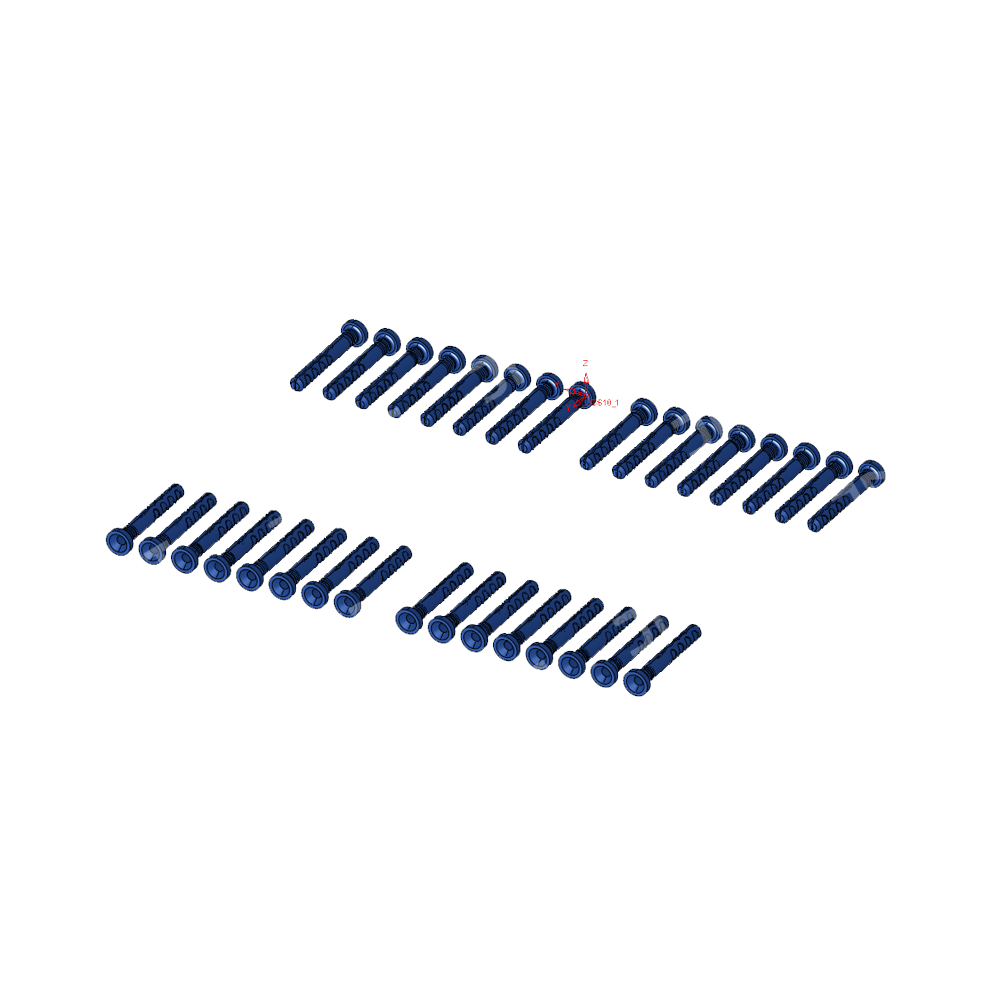

Because this product, expansion screw always need multi-cavities for one mould to produce more product, here have some features of multi-cavity:

Because the shrinkage rate will change due to injection pressure, therefore, for a single cavity mold, the cavity pressure within the cavity should be kept as consistent as possible. As for multi-cavity injection moulds, the pressure difference between cavities is very small. In the case of single cavity with multiple gates or multiple cavities with multiple gates, injection must be made at the same injection pressure so that the cavity pressure is consistent. Therefore, ensure that the gate position is balanced. In order to have uniform pressure in the cavity, the pressure at the gate of the injection mold needs to be consistent. The balance of pressure at the gate is related to the flow resistance in the runner. Therefore, before the pressure at the gate of the multi-cavity injection mold is balanced, the flow channel needs to be balanced.

|

Part Name

|

short plug Round head expansion screw plastic injection mould

|

|

Plastic resin

|

>PA6<

|

|

Mould cavity steel

|

H13

|

|

Mould Core steel

|

H13

|

|

Gate system

|

cold runner

|

|

Manufacture time (day)

|

50DAYS

|

|

Mould life

|

1,000,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Tel: +86-18158622819

Tel: +86-18158622819  E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى