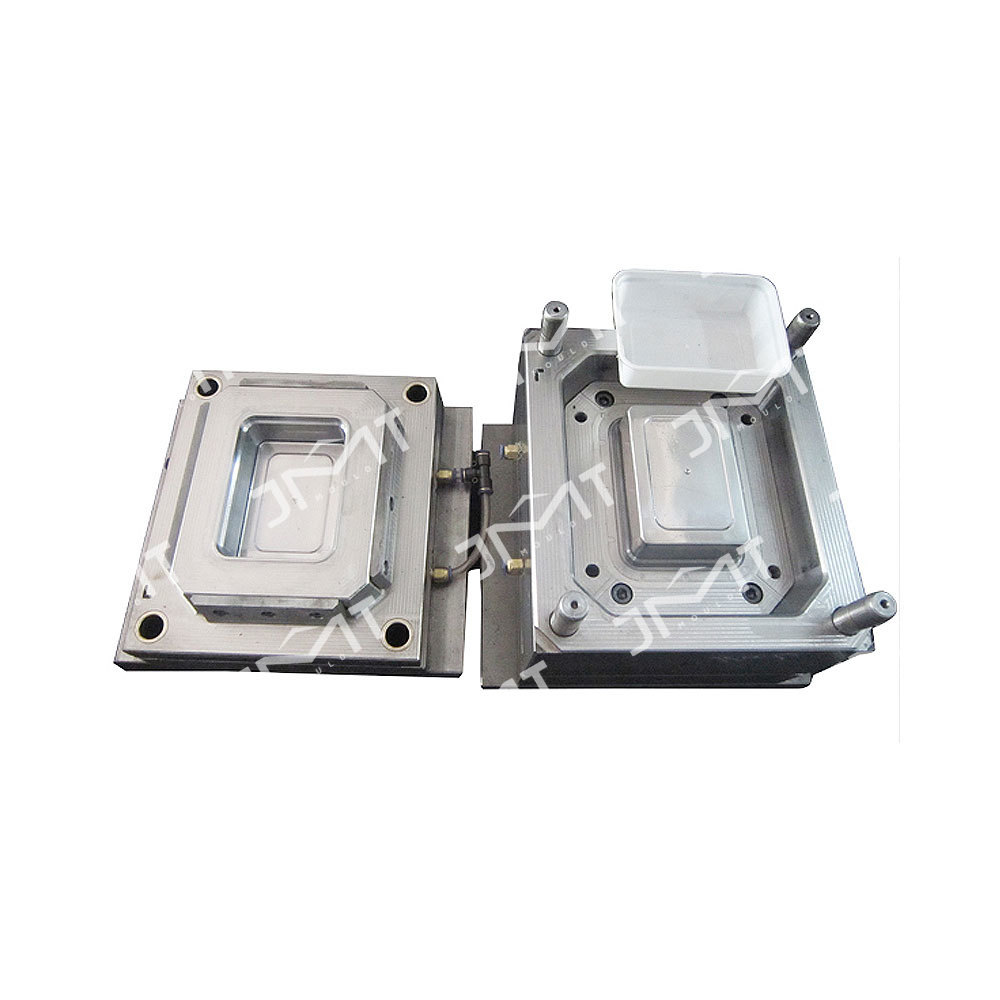

JMT Moulds is leading White Square disposable lunch box body packing box plastic mold suppliers and exporter, we provide a one-stop mould solution service, which includes mould components, mechanical design, mould design, mould manufacturing, plastic component manufacturing and secondary processing services. Also, JMT has invested the time and effort to be awarded the IATF 16949:2016 and ISO -001-2015 Quality Certification.

-

Tel: +86-18158622819

Tel: +86-18158622819 -

E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)