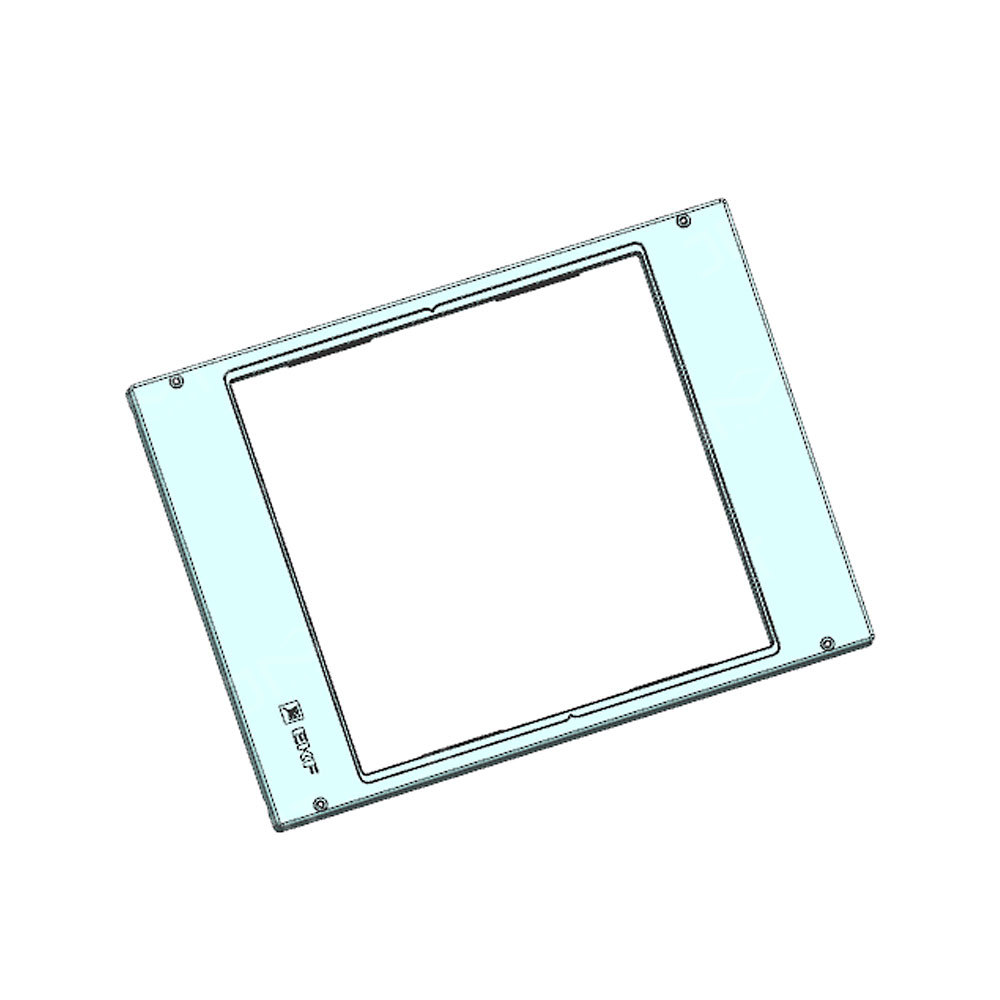

Importance of Plastic Electric Meter Box Frame Mould:

The frame mould serves as the foundation for the meter box, providing structural support and housing the components of the electrical meter. A high-quality plastic electric meter box frame mould offers several advantages, including:

Precision and Consistency: A well-engineered frame mould ensures precise and consistent production of meter box frames. This accuracy is crucial to maintain the proper alignment of components and facilitate seamless assembly during manufacturing.

Enhanced Efficiency: By utilizing an efficient frame mould design, the manufacturing process can be streamlined, resulting in increased production rates and reduced cycle times. This efficiency translates into cost savings and improved overall productivity.

Durability and Strength: The frame mould's design and material selection significantly impact the durability and strength of the meter box frame. High-quality moulds made from robust materials enable the production of frames capable of withstanding mechanical stress and environmental factors such as temperature variations and UV radiation.

Customization and Flexibility: With a well-designed frame mould, manufacturers can easily customize the shape, size, and features of the meter box frames to meet specific requirements. This flexibility allows for adaptation to different electrical meter models and facilitates easy integration with existing infrastructure.

Considerations in Designing and Manufacturing:

Designing and manufacturing a plastic electric meter box frame mould requires careful attention to various factors:

Material Selection: The choice of mould material is crucial for achieving durability, dimensional stability, and resistance to wear and tear. Common materials used for frame moulds include high-density polyethylene (HDPE) and acrylonitrile butadiene styrene (ABS), known for their excellent mechanical properties and resistance to environmental factors.

Precision Engineering: Accurate design and machining of the frame mould are essential to ensure consistent production of high-quality meter box frames. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies help optimize the mould's geometry and achieve tight tolerances.

Cooling System: An efficient cooling system integrated into the mould design helps regulate the cooling process, ensuring uniform cooling and reducing cycle times. Proper cooling also prevents warping and distortion of the meter box frames, leading to enhanced dimensional accuracy.

Maintenance and Repair: Regular maintenance of the frame mould is crucial to ensure its longevity and continued performance. Manufacturers should establish a maintenance schedule, including cleaning, lubrication, and periodic inspections to identify any wear or damage that may require repairs or replacements.

Plastic electric meter box frame moulds play a vital role in the production of durable, efficient, and customized meter box frames. By considering factors such as material selection, precision engineering, cooling systems, and maintenance, manufacturers can optimize their mould designs to achieve high-quality results. A well-designed frame mould ensures the consistent production of meter box frames that can withstand environmental stressors while facilitating efficient assembly and integration. Investing in the development of a reliable plastic electric meter box frame mould is an essential step towards enhancing the overall performance and longevity of electrical meter boxes.

English

English Español

Español عربى

عربى