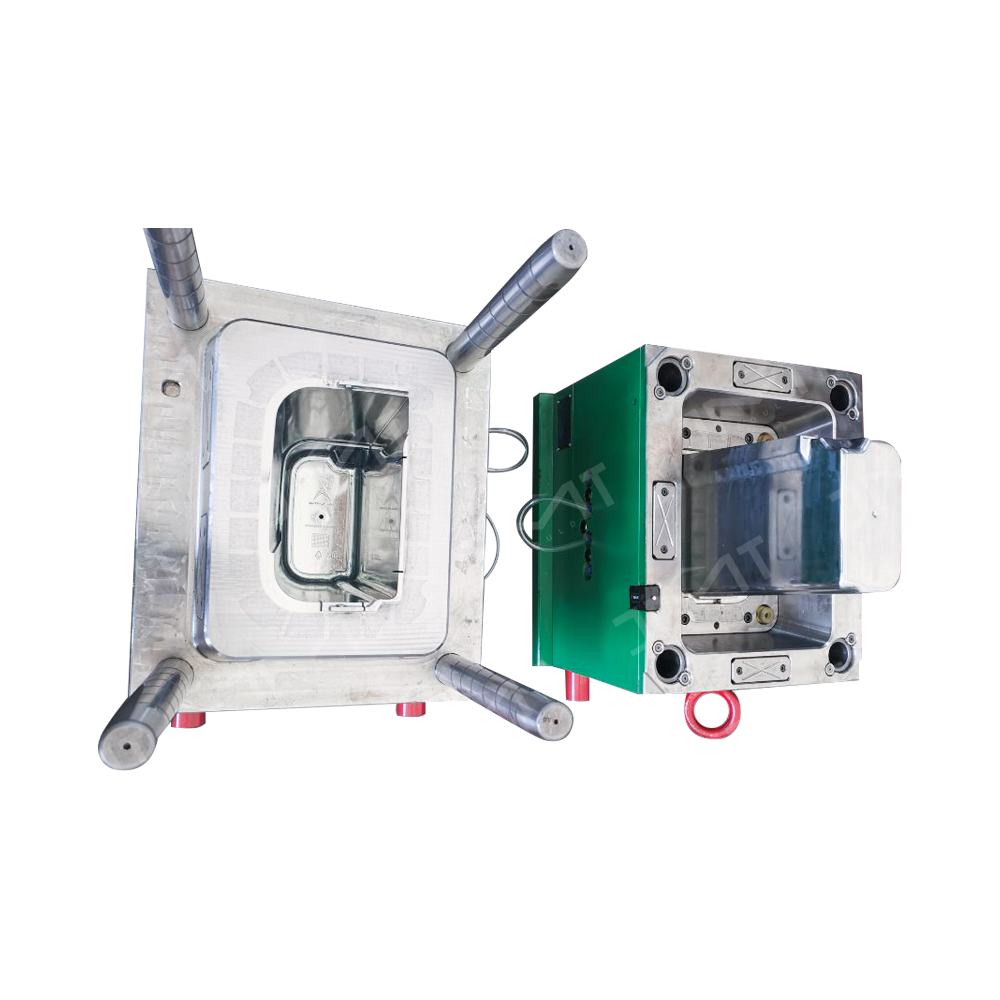

dustbin injection mould

The plastic dustbin is a mass produced product, which is usually manufactured using the process of injection moulding. The process involves injecting molten plastic into a mould to create the shape and size of the product. The material used for the production of this product is typically high-density polyethylene (HDPE), which is extremely durable and strong. After the plastic has cooled, the mould is opened and the solidified product is ejected.

One of the common types of dustbin injection moulds is the loose-bar type. This design overcomes the difficulty of ejecting a dustbin with a long draw. For example, a sliding box cover would have a four-inch draw. The opening travel in this case would require endwise molding. Alternatively, a bulky mold would be designed with space in the middle. Depending on the desired ejection action, the mould could be double the length of the dustbin.

A good quality plastic garbage bin injection mould should be designed to ensure durability and functionality. The mold steel, cooling system, and injection gate all contribute to a good quality product. These components will prevent the product from tearing apart during use. They are also easy to customize and are less expensive than stainless steel or iron garbage bins. You can choose from a variety of designs and colors and even add your own custom design elements. Once the mould is created, it is ready for use.

A clean oil is an essential part of the injection molding process. This type of moulding requires consistent temperatures and viscosity. A good oil maintenance unit will also prevent unplanned machine downtime. This is crucial as less maintenance equals higher productivity. This is why the best plastic injection moulds will also reduce maintenance costs. The process of injection moulding plastics is an excellent choice for those who want to maximize the efficiency of their processes.

The process of mold production requires a good grasp of materials and manufacturing needs. The hardness of the material chosen for production is vital, and the process of manufacturing molds can only be fully understood after examining its suitability. Once the material is selected, the manufacturer can ensure that the mold will meet the demands of repeated production. Only then can the final product be guaranteed quality and consistency. If the process is done correctly, the results are great.

plastic trash can mould

The Plastic Trash Can Mould can be manufactured in different types of factories, such as JMT mould, which is a professional manufacturer of such moulds. The company uses imported plastic and stainless steel for mould making, which ensures the high quality and precision of the product. The mold also uses pneumatic drive nozzle pin, which effectively controls the opening of the injection hole. The mould has low thermal expansion rate and smooth movement.

industrial trash can mould

An Industrial trash can mould is used to manufacture garbage bins. The moulds are made from plastic. These can be used in a wide range of industrial processes, including packaging, automotive, construction, and many other applications. These moulds are typically available for a reasonable price, with the majority of products requiring an order minimum of 50 pieces. The following is a list of key factors to consider when selecting a trash can mould.

With more than 18 years' experience in the industry, JMT moulds can produce a wide variety of dustbin moulds for your business. From plastic classification outdoor dustbins to pedal dustbins, JMT has you covered. And we can deliver them fast. You don't need to worry about assembling the moulds, because all of the parts of the product are already pre-assembled and ready to go.

English

English Español

Español عربى

عربى